3D Scanning and Modelling

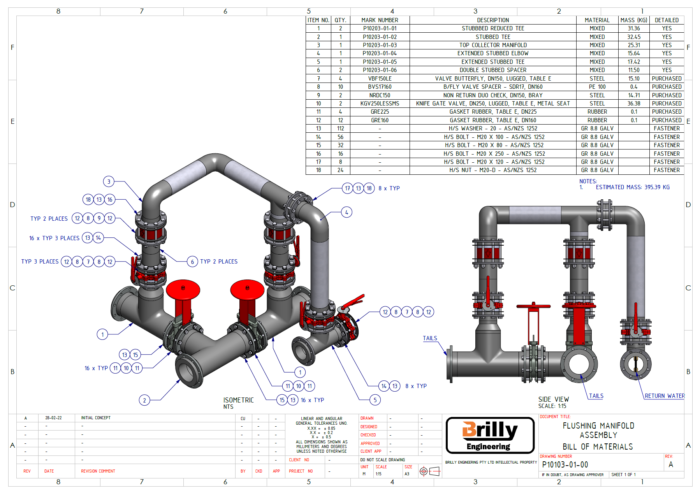

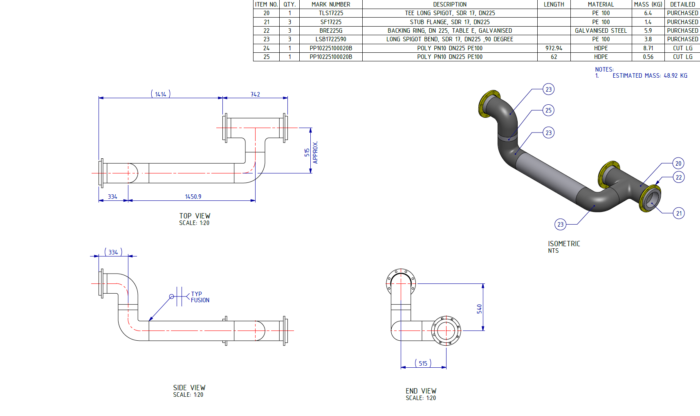

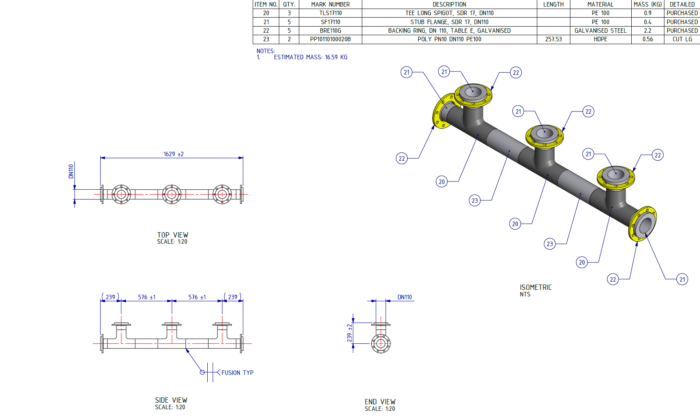

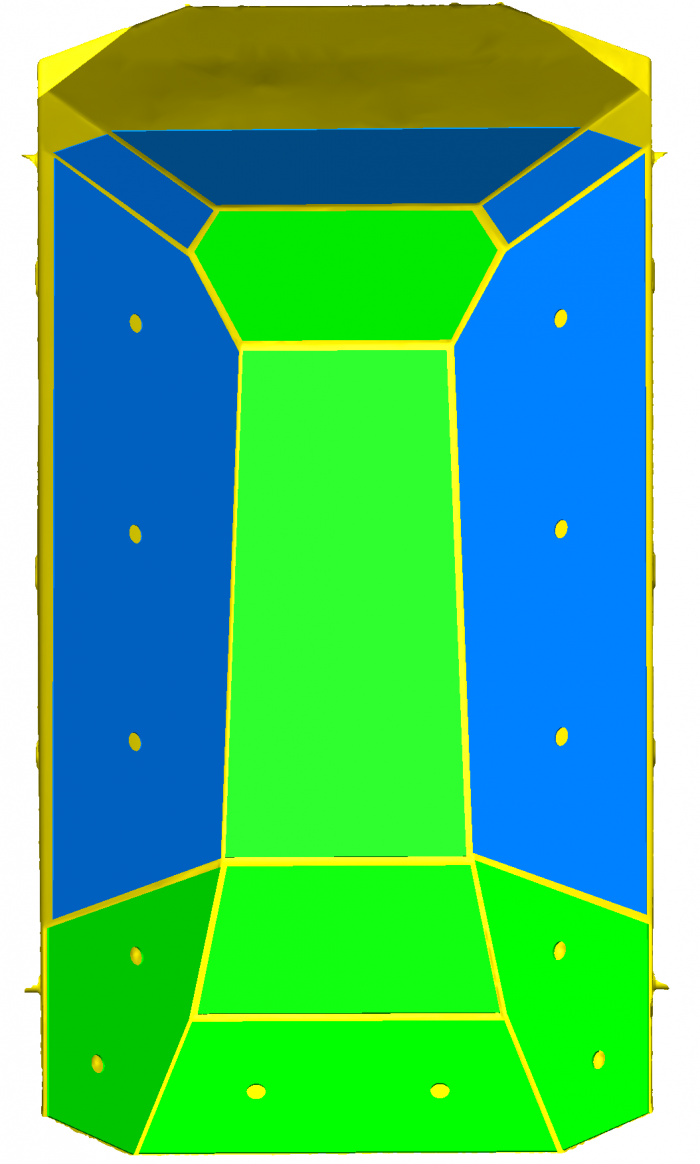

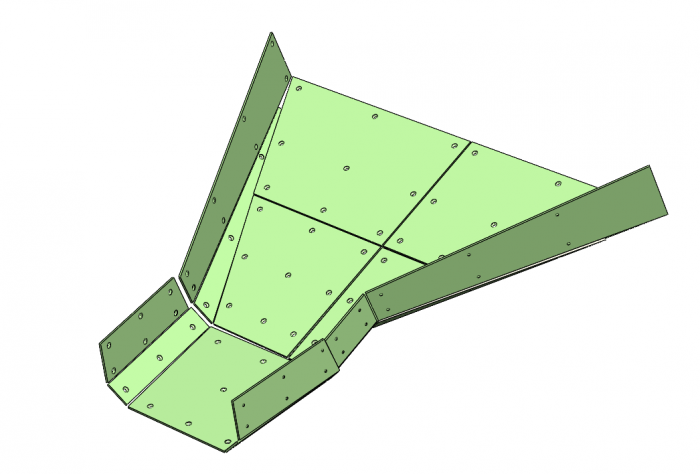

3D Scanning and modelling for HDPE pipe and metallic wear liners.

That’s Brilly.

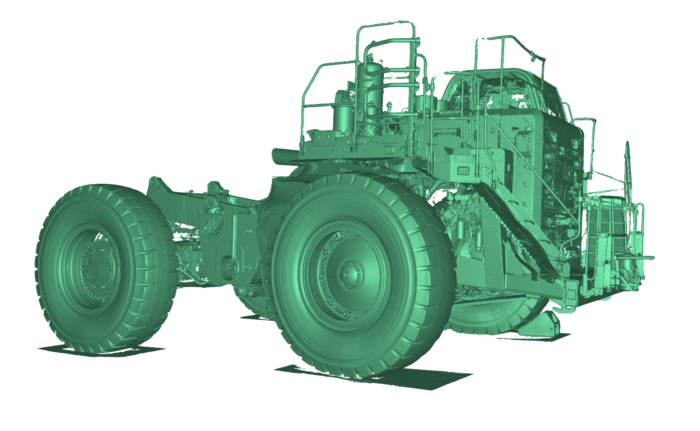

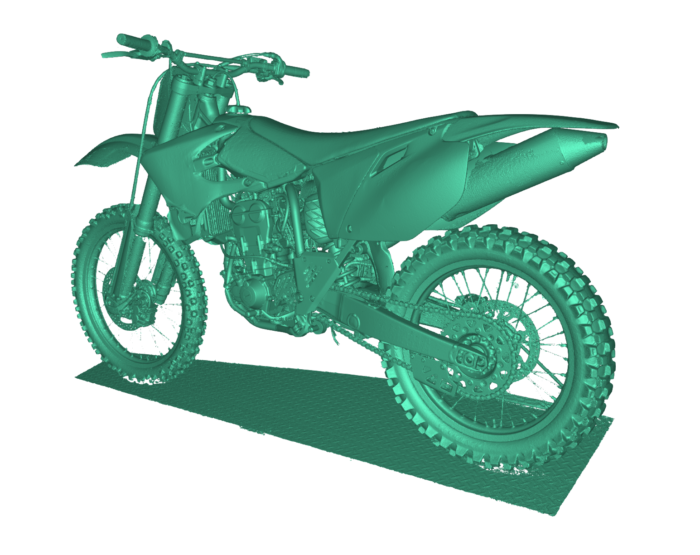

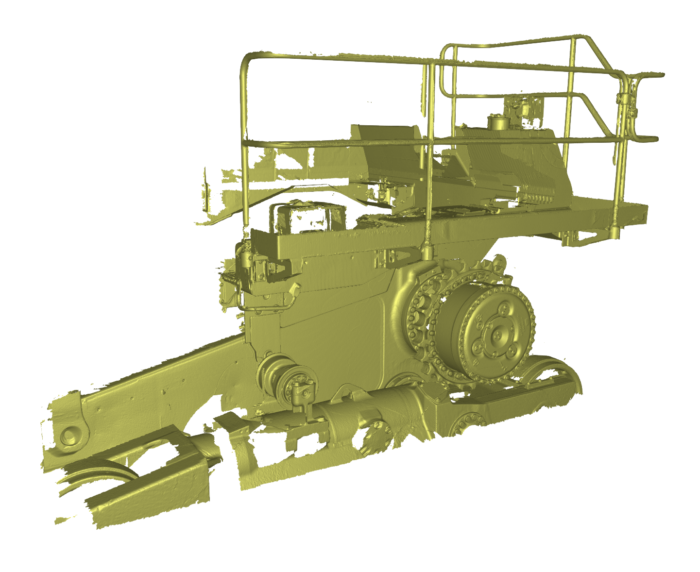

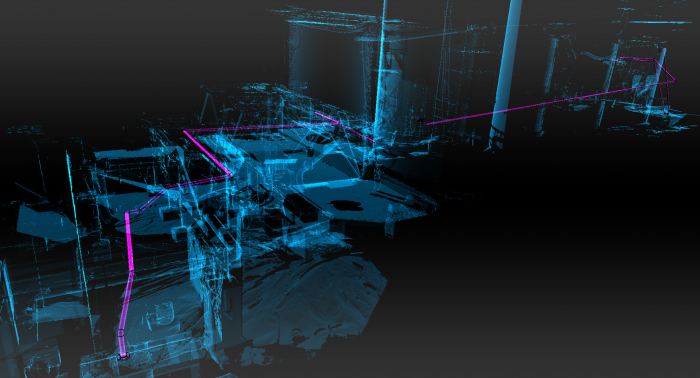

Brilly Engineering can capture measurements in a 3D space with sub-millimeter accuracy over long distances or in tight spaces.

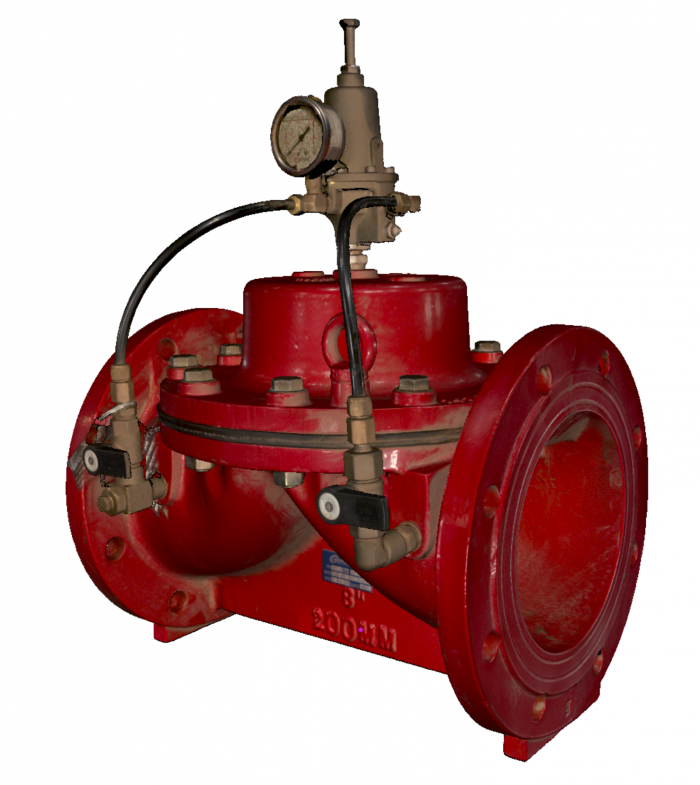

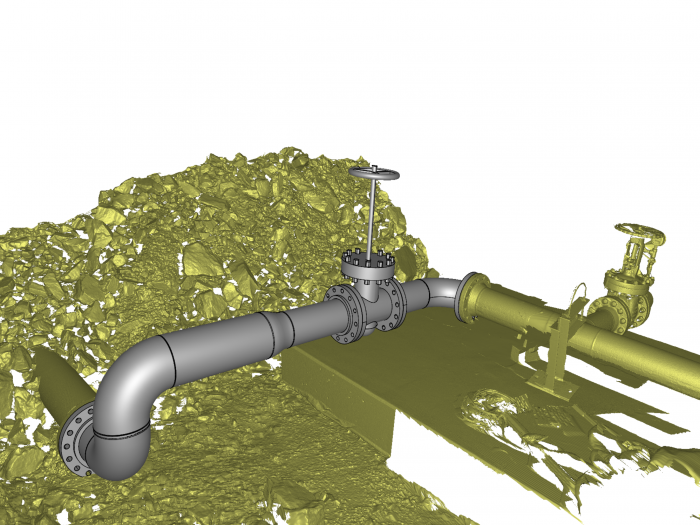

3D SCANNING

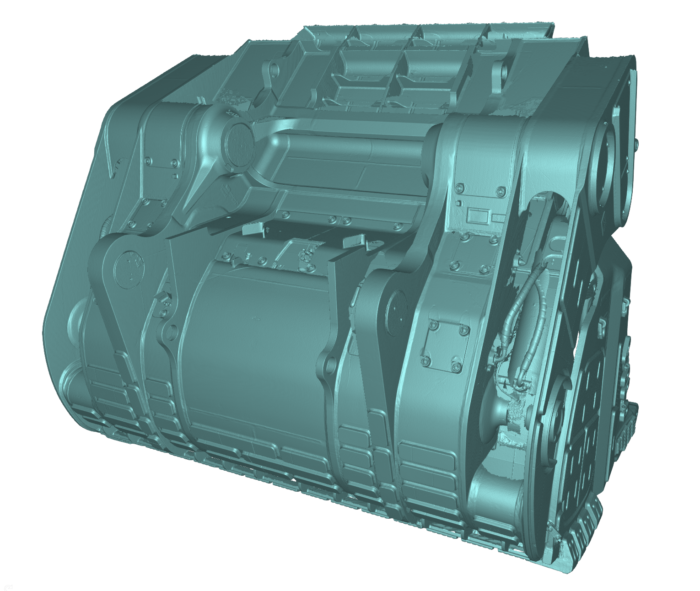

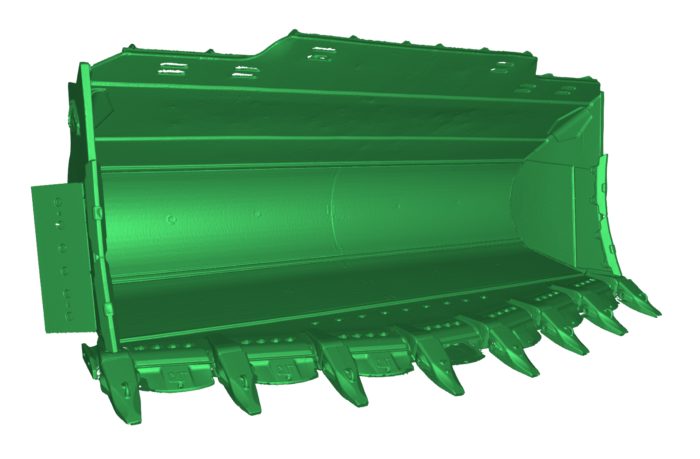

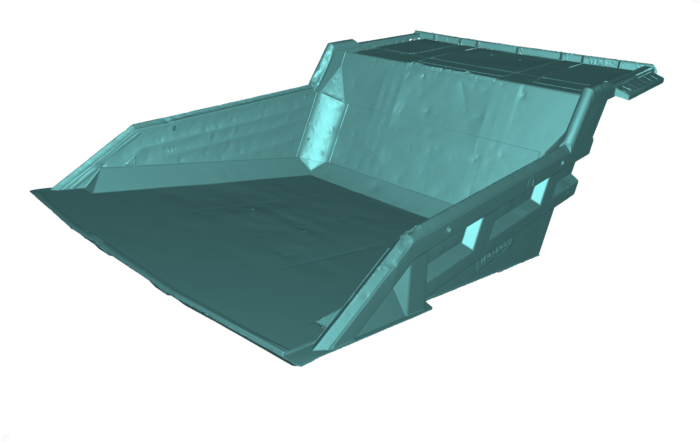

- Scanning of existing structures and piping for developing new HDPE pipe systems.

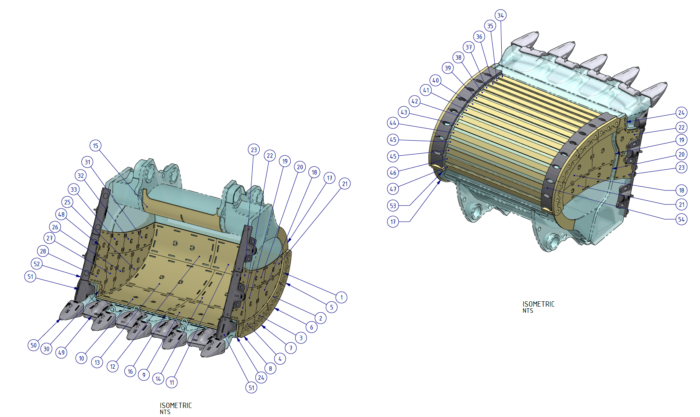

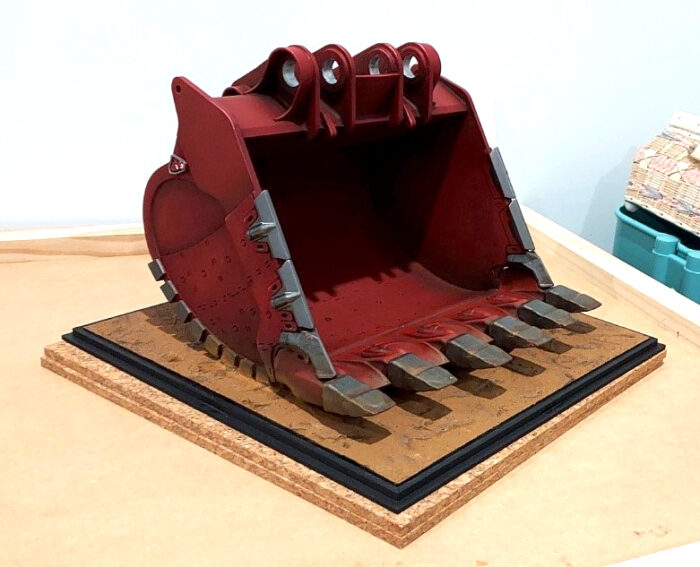

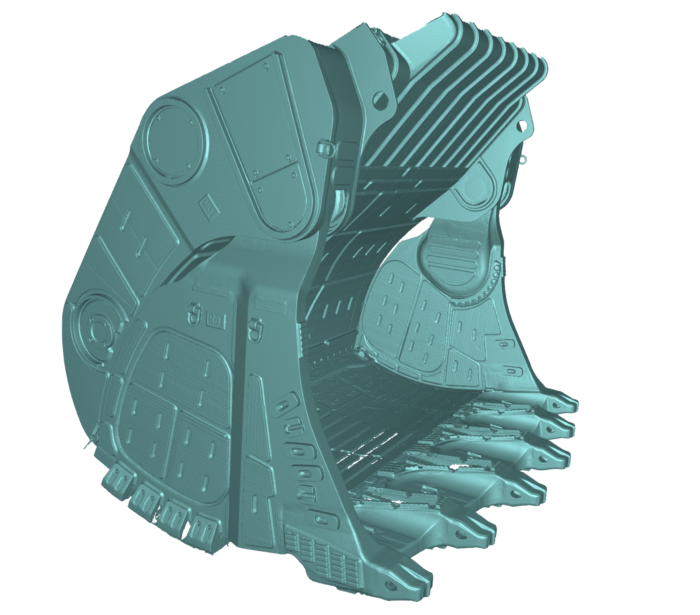

- Take measurements of wear liner arrangements on chutes, bins, crushers, ROMs, Buckets, trays safely due to using 3D Scanning.

- No drawings? Scanning of existing piping or wear liner arrangements allow accurate replication of layouts, making maintenance and replacement simple.

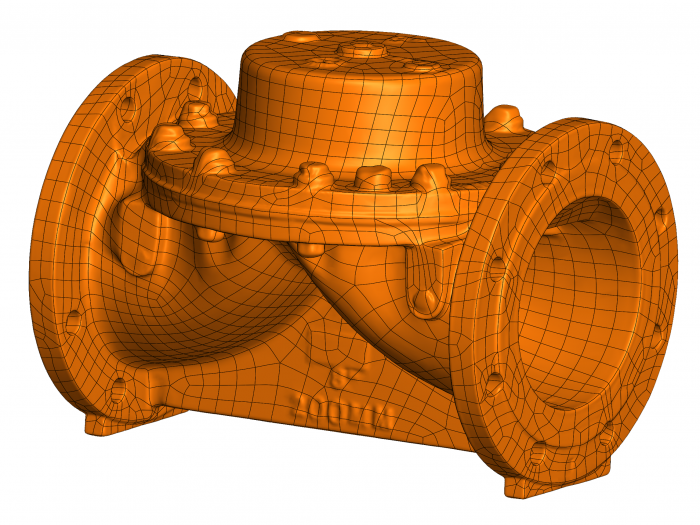

3D DATA SUPPLY

After scanning we can supply your engineering team with 3D data such as point clouds, 3D mesh and 3D solids.

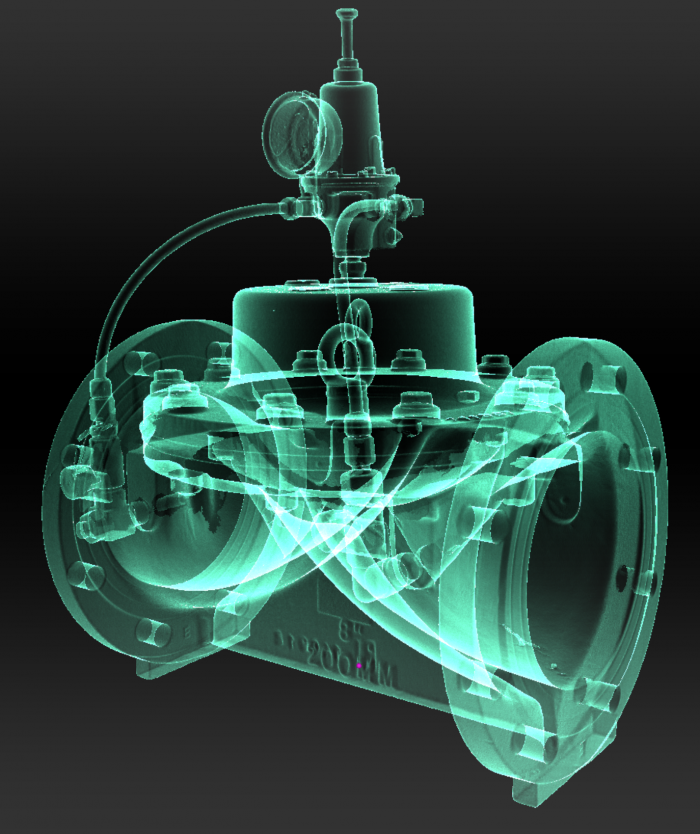

WEAR LINER INSPECTION REPORTING

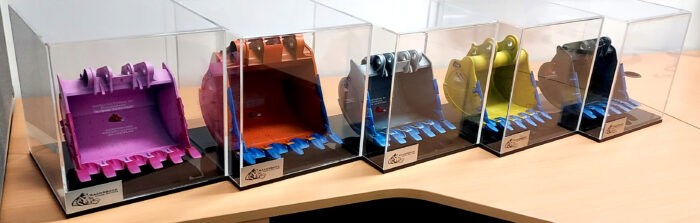

Visual inspection, thickness testing, 3D scanning and wear mapping reporting can be provided and summarised with recommendations.

WEAR LINER DEVELOPMENT

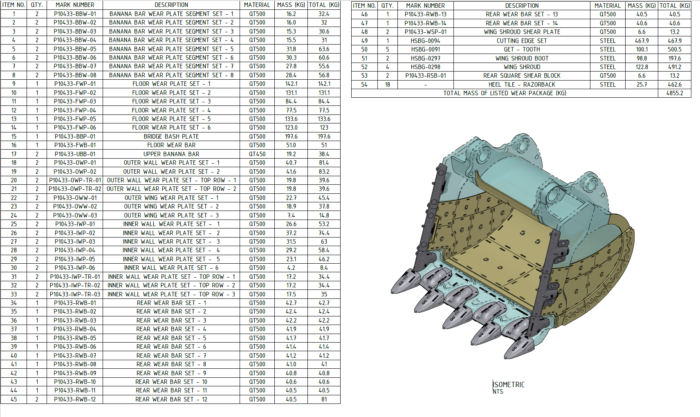

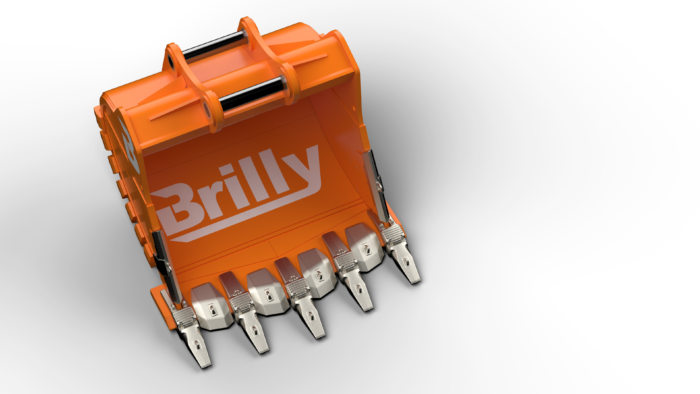

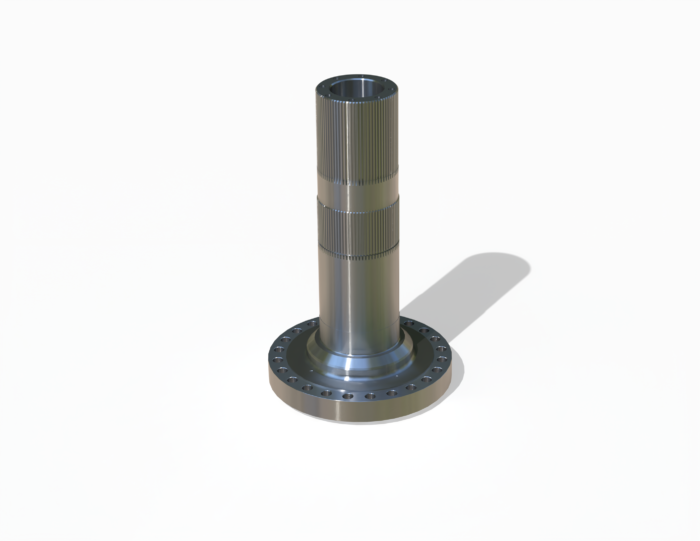

Develop specialised metallic, polyethylene and polyurethane wear liner packages to suit client requirements.